Porsche Pioneers Sustainable Energy Storage With Repurposed Taycan EV Batteries

Porsche’s Innovative 5 MW system Reduces Peak Loads And Enhances Grid Stability At Its Leipzig Plant

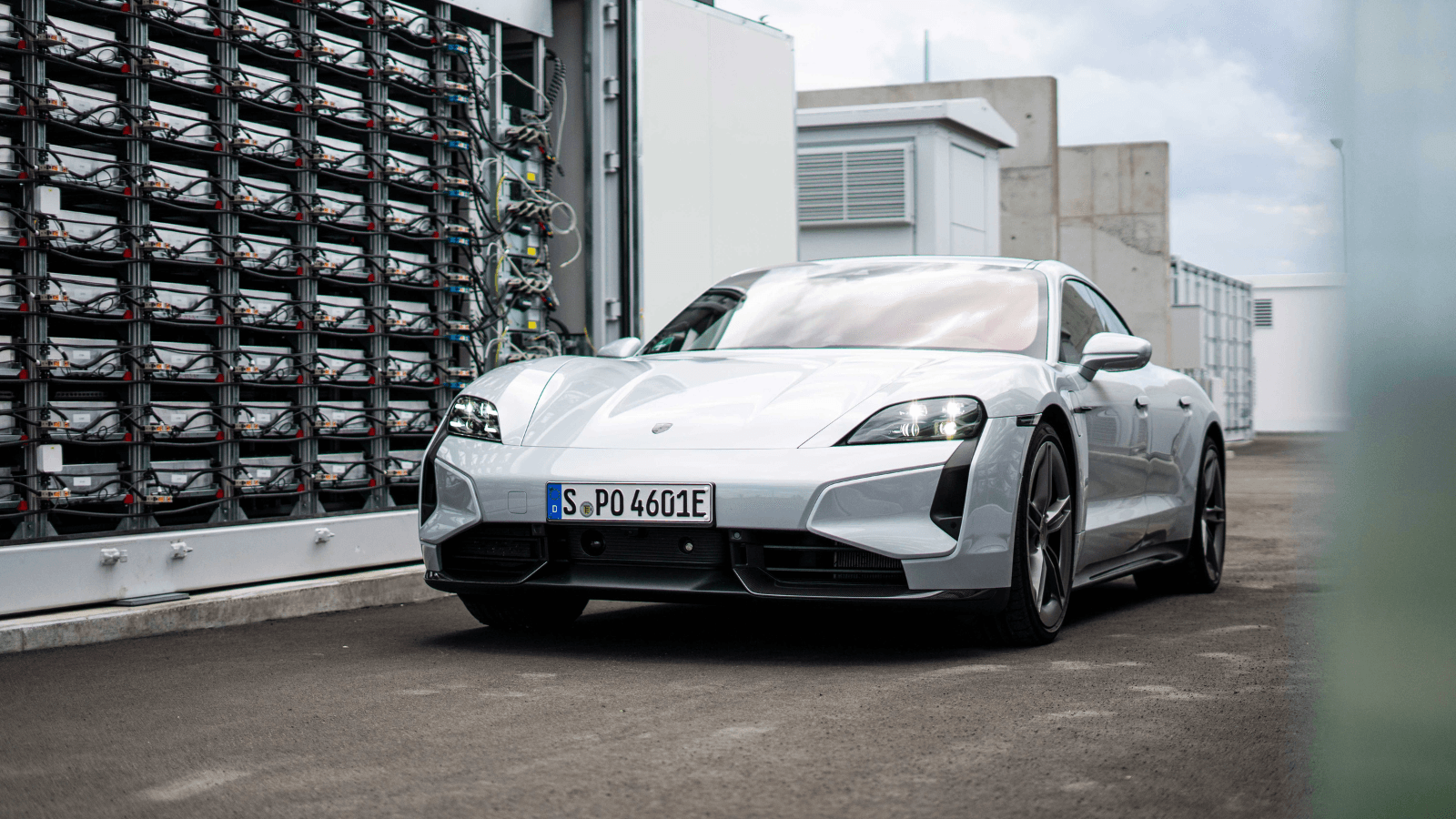

Porsche has taken a major step towards sustainable manufacturing by implementing an innovative energy storage system built using repurposed batteries from Taycan electric vehicles (EVs) at its Leipzig plant.

The new storage plant comprises 4,400 battery modules from pre-series and factory Taycan EVs. This “Second Life” concept demonstrates how high-voltage batteries from electric vehicles can be effectively reused, conserving resources and promoting sustainability according to Porsche.

With a capacity of 5 megawatts and 10 megawatt-hours of energy, the system can operate at up to 20% overload for short periods. Moreover, it is designed to reduce peak loads, optimize self-consumption, and participate in the energy market.

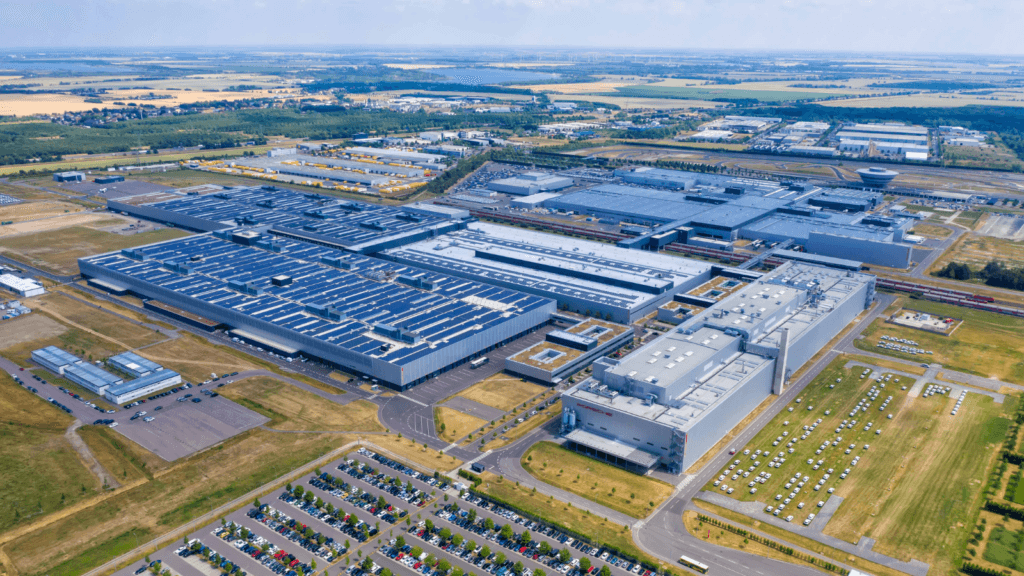

The system is partially powered by the plant’s solar installations, which have a peak output of 9.4 megawatts. By the end of the year, it will be fully integrated into the balancing energy market, serving as a grid stabilizer for upstream distribution grids.

Alwin Schmid, Head of Electrical Engineering at Porsche and the project’s initiator, expressed the multiple goals achieved stating, “In this unprecedented model project, we were able to combine a number of different goals, including peak load capping, optimization of self-consumption and simultaneous participation in the energy market.”

The project, which originated from Porsche’s Environmental and Energy Management unit, was based on a feasibility study conducted in collaboration with the University of Applied Sciences Zwickau. It not only addresses environmental concerns but also aims to increase the plant’s economic efficiency and self-sufficiency.

Jonathan Dietrich, the overall project manager for battery storage, explained the rationale behind using pre-series vehicle batteries: “We wanted to create electricity storage capacities for the Leipzig plant to make the site even more economical and to increase its degree of self-sufficiency. So it was only logical to use batteries from Taycan pre-series vehicles instead of recycling them.”

Furthermore, this initiative aligns with Porsche’s broader sustainability goals. Since 2021, production at Porsche’s sites in Zuffenhausen, Leipzig, and Weissach has been carbon-neutral, using only renewable energy sources. The Leipzig plant, in particular, receives energy from green electricity, biomethane, and district heating from biomass.

For Porsche’s Taycan model, the EV has been hitting hurdles as the company reported a steep 51% decline in Taycan deliveries with only 8,838 units sold globally in the first half of 2024, in contrast to 17,991 units in the same period last year. Also, the introduction of the updated 2025 Taycan model was unveiled in February with improvements in range, power, and charging speed. With the Porsche implementing tactics to reuse the Taycan model in different aspects, it shows the company’s innovative mindset in its sustainability strategy.

As Porsche’s innovative approach to battery reuse sets a new standard for sustainable manufacturing practices, the success of this project may pave the way for similar implementations at other Porsche locations, further solidifying the company’s actions in eco-friendly automotive production.

If you are looking for Porsche Taycan models, we can help you get started. Click Here to find the best deals near you. Want to learn more about EV? Thinking of buying an EV? Head over to EV.com and discover more.

Comments

Categories

Subscribe for EV News and Reviews

AI Employee for Car Dealerships

Results in 30 days - Or We'll Give You Your Money Back