Nissan Develops Innovative Cooling Paint That Reduces EV Energy Consumption

Nissan’s Innovative Metamaterial Paint Lowers Cabin Temperature By 9°F And Reduces Battery Strain

With efforts to enhance the efficiency and comfort of electric vehicles (EVs), Nissan has developed an innovative new automotive paint technology that uses electromagnetic waves to significantly lower cabin temperatures.

The paint, developed in partnership with Radi-Cool, a specialist in radiative cooling products, incorporates a unique metamaterial composition that reflects near-infrared rays from the sun and redirects energy away from the vehicle’s surface according to Nissan.

“My dream is to create cooler cars without consuming energy,” explained Dr. Susumu Miura, senior manager at Nissan’s Advanced Materials and Processing Laboratory. “This is especially important in the EV era, where the load from running air conditioning in the summer can have a sizable impact on the state of charge.”

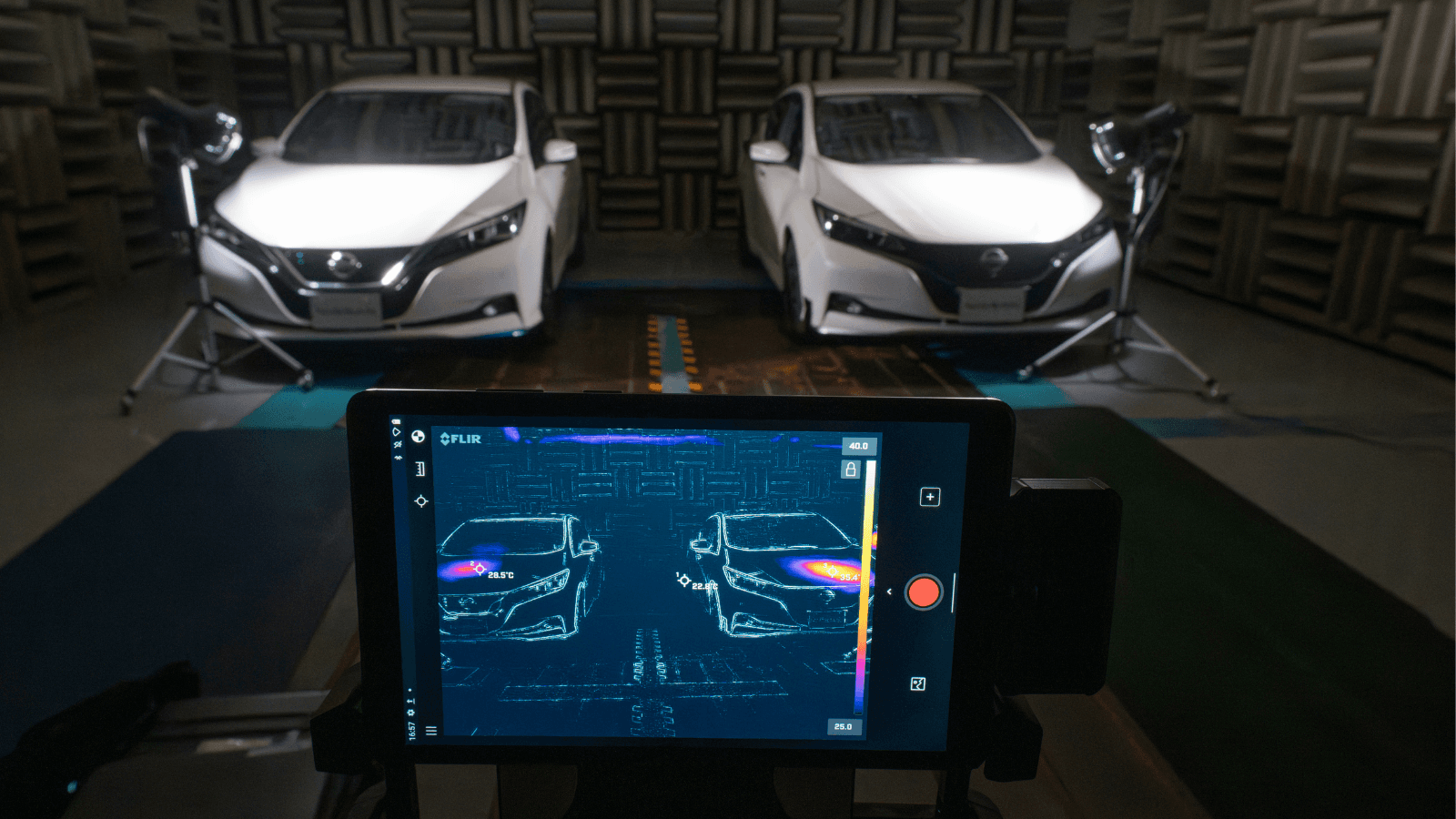

Preliminary testing of the new paint has yielded strong results. When parked side-by-side with a vehicle featuring traditional automotive paint, the vehicle treated with Nissan’s cooling paint showed a remarkable 12-degree Celsius (21.6-degree Fahrenheit) reduction in exterior surface temperature and a 5-degree Celsius (9-degree Fahrenheit) drop in cabin temperature.

According to Nissan, the key to the paint’s cooling performance lies in its metamaterial composition, which features two types of microstructure particles. One particle reflects near-infrared rays from the sun, while the other creates electromagnetic waves that counteract the sun’s rays, redirecting the energy away from the vehicle’s surface.

While radiative cooling paints have been used on buildings for years, Nissan faced several challenges in developing an automotive-specific version. The team had to ensure the paint could be applied through spray gun, incorporate a clear topcoat, and meet the company’s rigorous standards for durability, scratch resistance, and repairability.

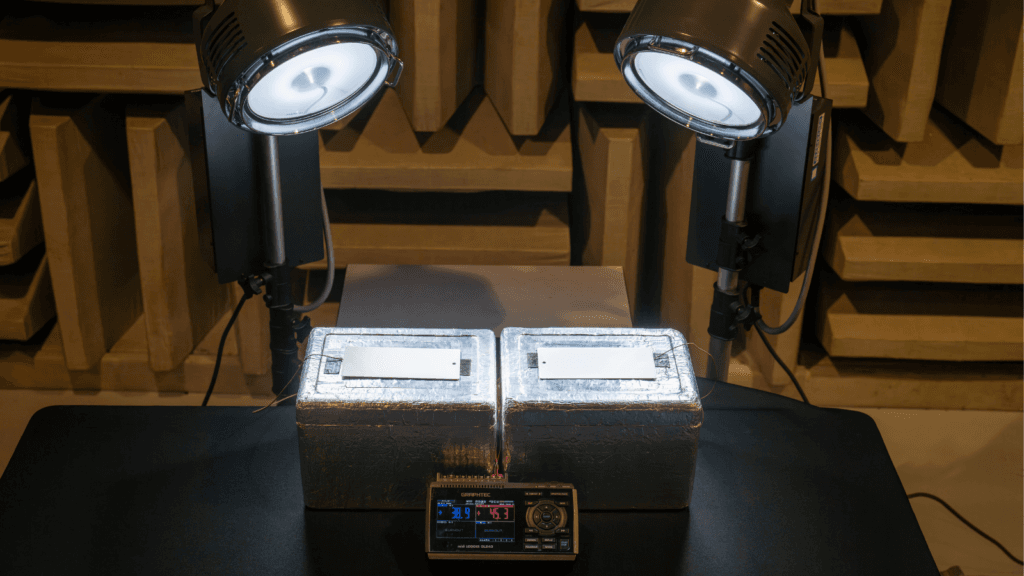

After testing over 100 samples since the project’s inception in 2021, Nissan has settled on a paint thickness of 120 microns, around six times thicker than a standard automotive finish. The current iteration has demonstrated resistance to salt, chipping, peeling, scratches, and chemical reactions, as well as consistent coloration and repairability.

As a result, the paint’s ability to keep surfaces cooler is particularly beneficial for EVs, as it can significantly reduce the energy required to cool the cabin, thus preserving the EV’s battery charge. This is especially crucial during prolonged periods of exposure to direct sunlight, such as when a EV is parked for an extended time.

Moreover, Nissan has started a 12-month feasibility trial of the cooling paint at Tokyo’s Haneda Airport, where the large, open tarmac provides an ideal environment for real-world evaluation under high-temperature conditions.

As the paint is still in the testing phase, Nissan will be aiming to bring its potential all its vehicles. With innovative technologies including this paint technology from Nissan, the actions to improving the EV experience is further addressed and will accelerate the transition to electric mobility.

If you are looking for Nissan models, we can help you get started. Click Here to find the best deals near you. Want to learn more about EV? Thinking of buying an EV? Head over to EV.com discover more.

Comments

Categories

Subscribe for EV News and Reviews

AI Employee for Car Dealerships

Results in 30 days - Or We'll Give You Your Money Back