Honda Revises Ohio EV Hub Strategy By Adding Hybrid And Gas Vehicle Production

The Acura EV Will Be First BEV Produced At Honda EV Hub In Late 2025

Honda has shifted plans on its approach to vehicle manufacturing with the establishment of its new electric vehicle (EV) Hub in Ohio as it announced plans for a flexible production system that will allow for the simultaneous manufacture of gas, hybrid-electric, and battery-electric vehicles (BEVs) on the same production lines.

According to Honda, the company’s Ohio plants are set to adopt flexible manufacturing capabilities, allowing the production of gas, hybrid, and EVs on the same assembly lines.

Despite previously aiming its Ohio EV hub as only for EV manufacturing, the company’s scale back and changing of plans are a result that displays a shift reflecting Honda’s plan of adapting its plants for current market trends and future electric mobility solutions.

Restructuring Manufacturing

Mike Fischer, executive chief engineer and Honda EV Hub lead, emphasized the transformative nature of this initiative stating, “Our efforts in establishing the Honda EV Hub in Ohio are not focused simply on EV production but on fundamentally reimagining our approach to manufacturing.”

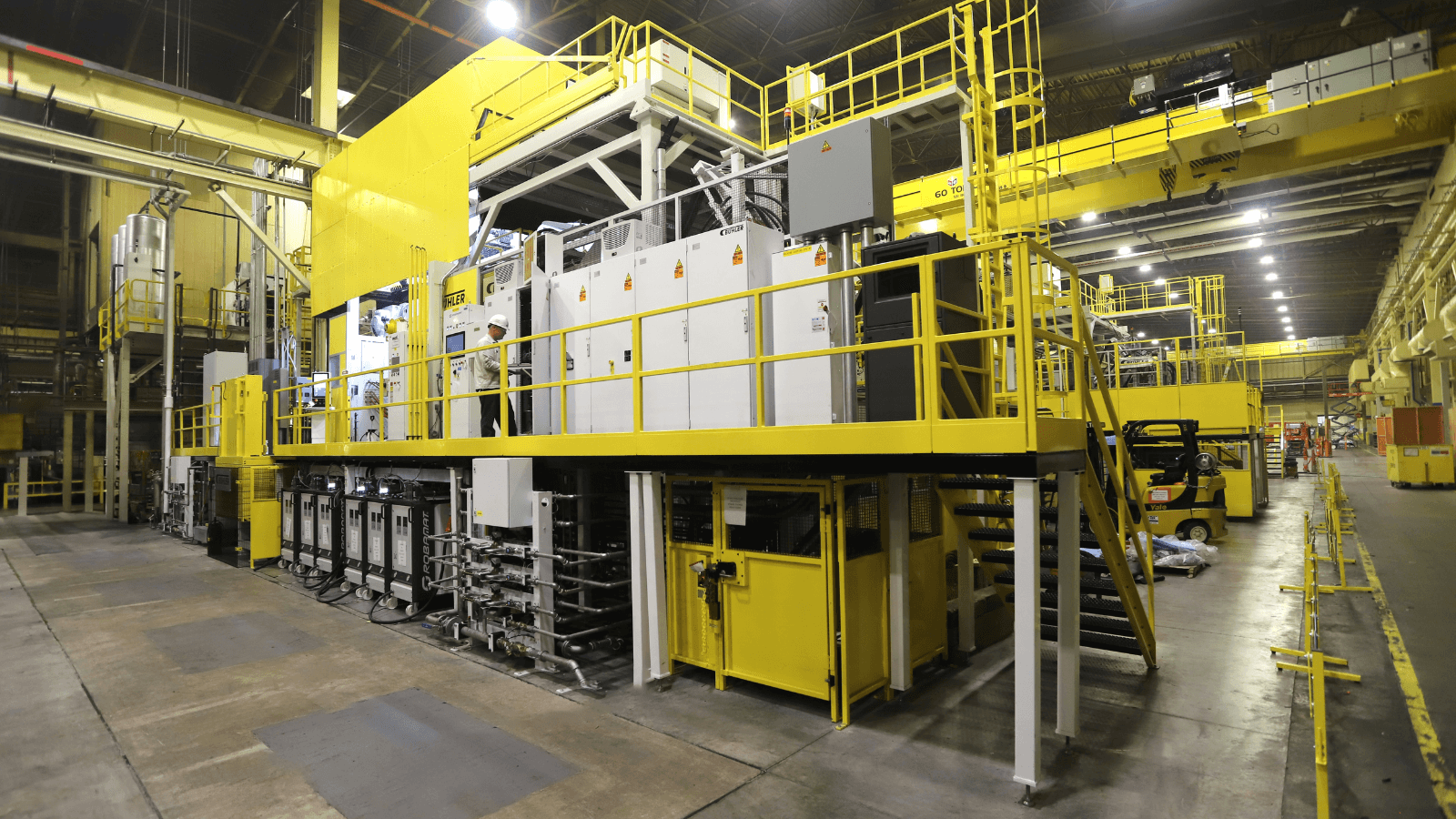

The retooling efforts at the Marysville Auto Plant, East Liberty Auto Plant, and Anna Engine Plant are underway. A key aspect is the installation of six 6,000-ton high-pressure die-cast machines at the Anna Engine Plant for megacasting the IPU cases, representing a new global capability for Honda.

With Honda’s new strategy, the company states that it enables Honda to meet current market demands while transitioning towards an electrified future. The Marysville Auto Plant will combine battery modules from the new joint venture battery plant with IPU cases from the Anna Engine Plant to create power units for different EV models.

Notably, the transformation extends beyond just EV production. Honda is focusing on creating a more efficient and environmentally friendly production environment. This includes optimizing layouts to reduce walking distances for workers, simplifying manufacturing processes, and improving parts delivery systems.

“We are truly going back to zero, transforming our production environment to more human-friendly and environmentally responsible processes and materials,” Fischer stated.

Honda’s Road Ahead

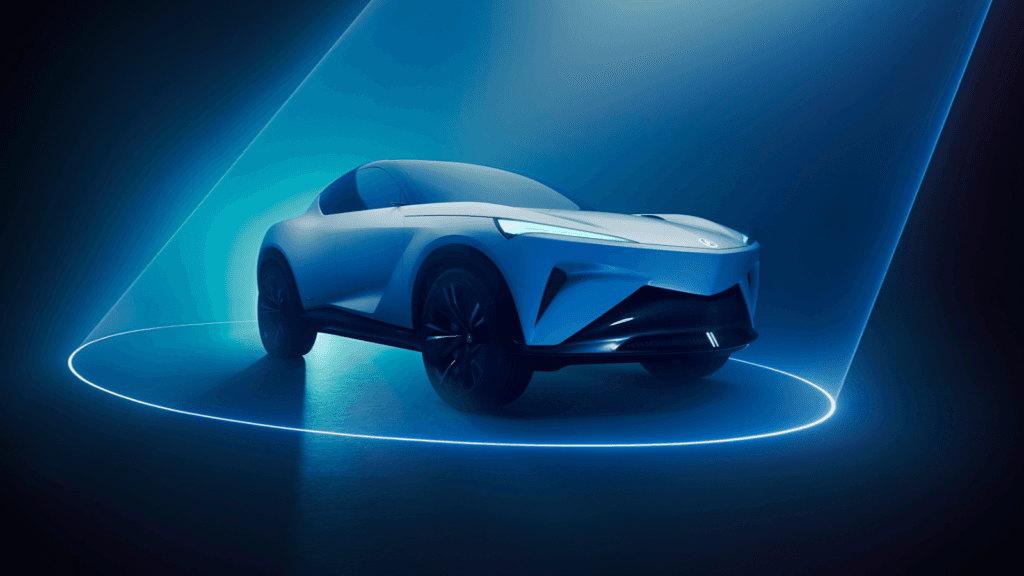

Moreover, the company’s first EV to be produced in Ohio will be based on the Acura Performance EV Concept, with production beginning at the Marysville Auto Plant in late 2025.

To support this shift, Honda is investing $700 million to retool its Ohio plants. In addition, a joint venture with LG Energy Solution will result in a $4.4 billion investment to build a new battery plant. These investments are pivotal to Honda’s EV strategy.

Honda is also introducing innovative technologies at its Ohio plants, such as megacasting at the Anna Engine Plant, which will allow for the production of larger Intelligent Power Unit (IPU) cases for EVs. This advancement will streamline production and enhance efficiency.

Honda’s manufacturing evolution is centered around a human-centric approach, making processes more environmentally responsible and worker-friendly. This transformation aligns with the company’s broader vision to achieve 100% battery-electric sales by 2040.

With Honda continuing its path on its revised EV manufacturing strategy, these advancements reflect a adjusted vision that positions the automaker to still look forward to reach the forefront of the EV industry.

If you are looking for Honda models, we can help you get started. Click Here to find the best deals near you. Want to learn more about EV? Thinking of buying an EV? Head over to EV.com discover more.

Comments

Categories

Subscribe for EV News and Reviews

AI Employee for Car Dealerships

Results in 30 days - Or We'll Give You Your Money Back